What do you get when you cross traditional production with digital technology, interconnectivity, big data and artificial intelligence?

Industry 4.0.

You’ve probably heard of this term. It’s been kicking around for a while now. It’s all about taking a more connected, holistic approach to manufacturing. About leveraging real-time data and smart, autonomous systems to boost productivity and improve processes.

But is it just for the big players or can medium-sized manufacturers of low-volume/high-mix products get in on the act? We decided to check it out. Here’s how…

Ready for another industrial revolution?

Many companies have already embraced industry’s fourth revolution. Some like Microsoft, General Electric, Siemens, Amazon and Bosch even help drive it. But there are many more smaller businesses who still aren’t sure how Industry 4.0 would benefit them or even how to go about upskilling their workforce.

At VRR, we’re definitely in the last category. But we pride ourselves on constantly evolving. Changing with the times and not being afraid of new technology is how we’ve managed to create innovative products for the air cargo industry since 1946.

However, before we become fully paid-up revolutionaries, we thought it wise to dip our toes in first and see what all the fuss is about. And we’re doing that by exploring a specialised area of advanced robotics: collaborative robots.

Smart and safety-conscious assistants

Known as ‘cobots’, collaborative robots are designed to work safely around people (not replace them) so they don’t have to do repetitive or dangerous tasks. Often smaller and lighter than your typical industrial robot, cobots are easy to program, operate at a constant standard, and can perform multiple tasks. What’s more, they have built-in safety features like sensors to avoid injuring nearby workers.

International Federation of Robotics: Demystifying Collaborative Robots

International Federation of Robotics: Demystifying Collaborative Robots

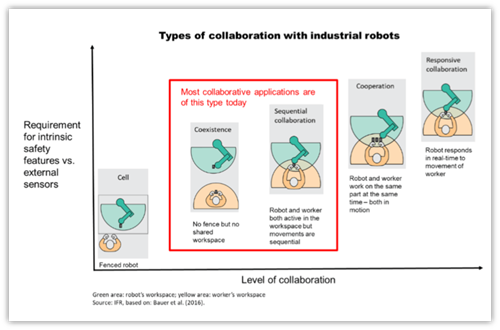

According to the International Federation of Robotics (IFR), a cobot has four types of collaboration:

1. Co-exist (work alongside a human and there’s no overlapping of tasks)

2. Collaborate sequentially (work alongside a human but their movements are in sequence)

3. Co-operate (work alongside a human on the same task)

4. Collaborate responsively (respond in real-time to the actions of a human)

The IFR is optimistic about the future of cobots. It expects almost 2 million new units to be installed in factories around the world between 2020 and 2022. The programming and installation of industrial robots is becoming much easier, helping manufacturers and others adopt new technology trends and react to ever quicker market developments.

Constantly learning and sharing

Not far away from us, in the Dutch town of Kampen, DHL has been experimenting with a particular type of cobot called autonomous mobile robots (AMRs). The express carrier was keen to see how they would interact with its employees and simplify their point-to-point material handling in a warehouse environment.

As it turns out, the AMRs are pretty amazing. They not only know how to navigate normal warehouse operations, avoiding both static and moving obstacles, like pallets and forklift trucks, but they’re constantly learning and sharing the most efficient travel routes to maximise overall pick efficiency.

DHL reckons that the AMRs have already saved their pickers walking up to 32km per day. In addition, they’ve reduced order cycles by up to 50% and allow workers to focus on more rewarding tasks.

A small step towards automation

Like DHL, we’re keen to use technology to free up our skilled workers and improve productivity at the same time, but rather than using an AMR for our experiment we’re using a welding cobot. Why kick off with a delicate task like welding, you may ask? There are several reasons:

• It’s getting harder and harder to recruit skilled welders

• It’s a relatively low-cost alternative to traditional robotic welding solutions

• The transition from manual to robotic welding doesn’t require many operational changes

• Operators can manage robot programs and change welding tools easily and quickly

• Cobots are perfectly designed for welding tasks in low volume/high-mix fabrication shops

Above all, it allows us to take a small step into the big world of automation without making a huge investment or massive changes to our factory layout.

The ideal colleague: happy to do the boring stuff

The welding cobot, which consists of a single arm with a welding gun on the end, moves up and down and forwards and backwards, tracking the workpiece. It works alongside our human welder, helping them move faster and speed up production.

Of course this doesn’t mean that a robot can replace welders altogether; there are some complex welds that still need a human touch. The repetitive welding moves are taken out of the welders hands so they can perform more interesting, added-value jobs. It’s a great partnership.

A welcome introduction

So far, our dabble with Industry 4.0 is proving to be exciting and rewarding. The welding cobot has introduced us to a new level of technology—one that we’re keen to explore further.

Want more information about the products we make with the help of Industry 4.0? Reach out to us via our contact form.

%20resize%20web.jpg)